ETI CAPABILITIES

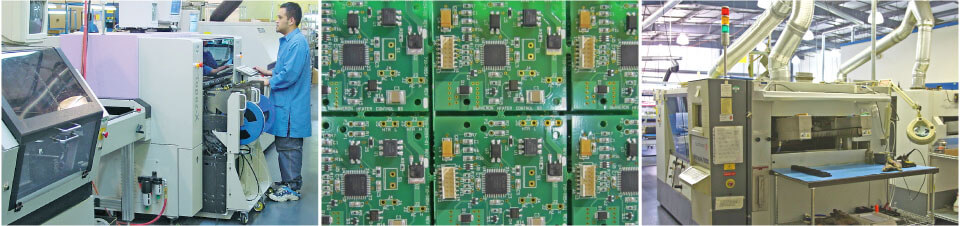

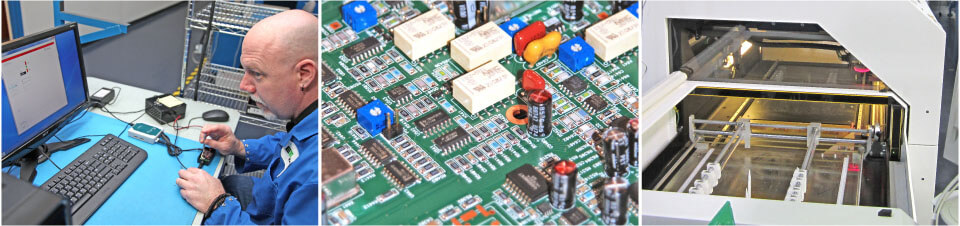

Double sided Surface Mount Technology (SMT), Through Hole (PTH), or Mixed Technology Assembly

RoHS (Lead-Free) Capable

Quick Turn Prototypes

Circuit Boards up to 18” x 24” and 32 layers

In-Circuit and Functional Testing

Design For Manufacturability (DFM) Assistance

Full or Partial Box Build

Customer Drop Ship

Wire Processing & Wire Harnesses Fabrication

Equipment

Assembleon Pick and Place

- 18000 components per hour

- BGA, µBGA, CSP, odd components

- .012” fine pitch

- 0201 components

- Connectors up to 4” (100mm) long

Spea In-Circuit Tester

- Analog and Digital device testing

- AOI optical inspection

Ekra Automated Stencil Printer

- Up to 29” x 29”

- Vision alignment

- Post print vision inspection

Heller Convection Reflow oven

Vitronics IR Reflow Oven

- Seven thermal zones

- KIC thermal profiling software

OK Industries BGA Rework Station

- BGA, µBGA, CSP, Fine Pitch Rework

- Computer controlled profiling software

- Vision alignment of component to PCB

Glenbrook X-Ray Station

- X-Ray inspection of BGA, µBGA, CSP or any other component

Electrovert Wave Solder

- Up to 18” board width

Component Lead Forming Equipment

- Hepco, Mark V, ADP

Westkleen Aqueous Cleaning System (with Closed loop filtration)